PRODUCT CENTER

FOAMING REGULATOR H-901

Classification :

FOAMING REGULATOR AGENT

Keywords:

FOAMING REGULATOR AGENT

DESCRIPTION

H-901 is widely used for rigid PVC products such as PVC windows profile, PVC pipes, especially for PVC foaming products, WPC product, etc.

KEY PROPERTY

▪ Improve the melt strength of PVC compound.

▪ Super fusion.

▪ Promote uniform & close cell structure.

▪ Provide excellent metal release property.

▪ Improve the glossiness of the products.

PRODUCT INDEX

Item | Unit | Test standard | Specification |

Appearance | - | - | White powder |

Bulk density | g/cm³ | GB/T 1636-2008 | 0.45±0.10 |

Sieve residue (30 mesh) | % | GB/T 2916 | ≤ 1.5 |

Volatile content | % | ASTM D5668 | ≤ 2.0 |

| Intrinsic viscosity (η) | - | GB/T 16321.1-2008 | 13.0-14.5 |

BASIC FORMULATION FOR FOLLOWING TESTS

Mixing equipment type: SHR-5A from Zhang Jiagang Beier Machinery Co., Ltd

Mixing condition: 50Hz, 120℃ emptying Volume: 5.0L

Ingredients | 1# | 2# |

Competitor | H-901 | |

PVC (K-65) | 100.00 | 100.00 |

Lead stabilizer | 4.40 | 4.40 |

TiO2 (Rutile) | 4.00 | 4.00 |

PE wax | 0.40 | 0.40 |

OPE wax | 0.60 | 0.60 |

AC blowing agent | 0.70 | 0.70 |

NaHCO3 | 1.30 | 1.30 |

Int. lubricant LU-60 | 0.80 | 0.80 |

CaCO3 (PCC) | 50.00 | 50.00 |

Acrylic impact modifier | 3.00 | 3.00 |

Lubricating processing aid | 2.00 | - |

Foaming regulator | 15.00 | - |

Foaming regulator H-901 | - | 13.00 |

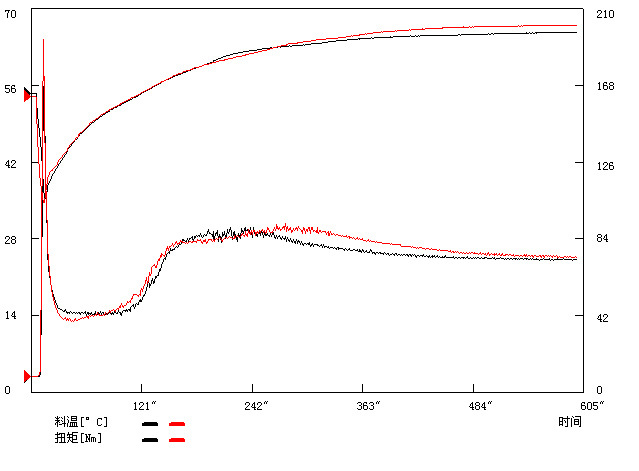

FUSION PROPERTY COMPARISON

Test equipment type: RM-200C torque rheometer from Harbin Hapro Electrical technology Co., Ltd Volume: 60ml

Test conditions | 160℃ 60rpm | ||

| |||

Fusion/Type | Fusion time (S) | Fusion torque (Nm) | Equilibrium torque (Nm) |

1#COMPETITOR | 158 | 28.5 | 24.4 |

2#H-901 | 151 | 27.5 | 25.0 |

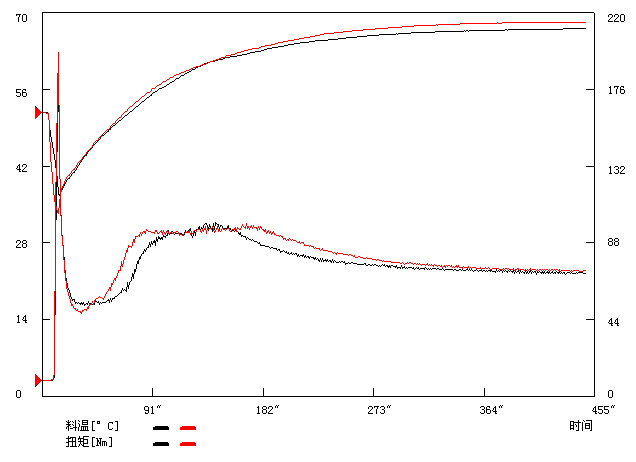

Test conditions | 160℃ 90rpm | ||

| |||

Fusion/Type | Fusion time (S) | Fusion torque (Nm) | Equilibrium torque(Nm) |

1#COMPETITOR | 89 | 30.2 | 22.5 |

2#H-901 | 73 | 30.5 | 23.2 |

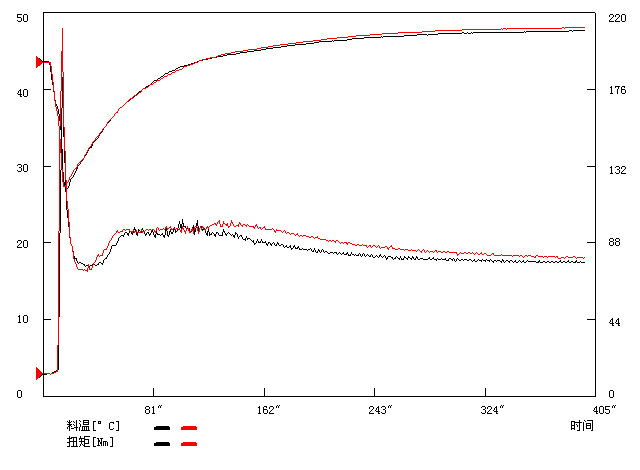

Test conditions | 190℃ 60rpm | ||

| |||

Fusion/Type | Fusion time (S) | Fusion torque (Nm) | Equilibrium torque(Nm) |

1#COMPETITOR | 50 | 21.5 | 17.5 |

2#H-901 | 45 | 21.7 | 18.2 |

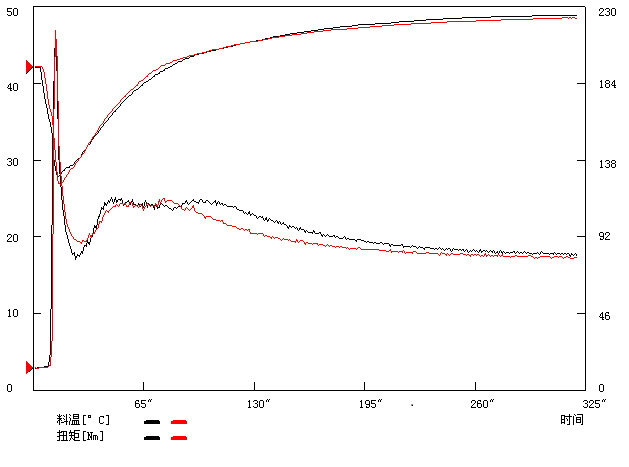

Test conditions | 190℃ 90rpm | ||

| |||

Fusion/Type | Fusion time (S) | Fusion torque (Nm) | Equilibrium torque(Nm) |

1#COMPETITOR | 38 | 24.4 | 17.4 |

2#H-901 | 33 | 25.1 | 18.0 |

METAL RELEASE PROPERTY COMPARISON

Dynamic thermal stability and sticking time on double-roller mill at 196℃

Time | △E with different time | Sticking time(s) | ||

| 4' | 6' | 8' | ||

1#COMPETITOR | 0.35±0.03 | 0.49±0.04 | 0.70±0.02 | 1297±10 |

2#H-901 | 0.35±0.03 | 0.40±0.03 | 0.63±0.02 | 1365±15 |

MELT FLOWABILITY OF PVC COMPOUND

Test equipment: Melt flow rate meter Test standard: ASTM D1238

Melt flow rate (g/10min) | |

Test condition | 220℃ 3.8kg |

1#COMPETITOR | 3.46±0.21 |

2#H-901 | 4.18±0.26 |

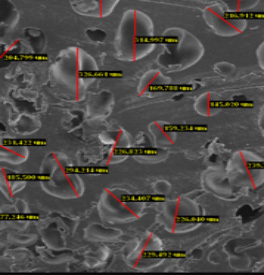

FOAM CELL STRUCTURE (SEM)

1# COMPETITOR | 2#H-901 |

|

|

SURFACE QUALITY OF EXTRUDED FOAMING SHEET

Type: Free foaming advertising board Thickness: 20mm

Type | Gloss (45℃) | Hardness | Density (g/cm³) |

Test standard | ASTM D2457 | GB/T 24137 | GB/T 6343 |

1#COMPETITOR | 9.1±0.2 | 64.2±0.2 | 0.61±0.02 |

2#H-901 | 12.5±0.2 | 68.4±0.3 | 0.55±0.03 |

STORAGE

The product should be stored in cool and dry surroundings.

The shelf life is two years, it can be still used if qualified by inspection after shelf life.

PACKAGE

25kg/bag with PP bag or customized packaging according to customer requirements.

LOADING CAPACITY

For 20GP container, we can load 16mt with pallets or 18mt without pallets.

For 40HC container, we can load 28mt with pallets or 28mt without pallets.

Factory

Customer visits

Delivery site

GET A FREE QUOTE

If you have any questions, please feel free to leave us a message at any time