PRODUCT CENTER

MBS IMPACT MODIFIER MBS-200

Classification :

MBS

Keywords:

MBS

DESCRIPTION

MB-200 is a type of transparent MBS impact modifier. It has dual benefits with balance of mechanical properties and optical properties. It is environmentally friendly and mainly used to produce clear PVC sheet and film with balance of transparency and impact strength.

KEY PROPERTY

▪ Promote fusion

▪ Balance of transparency and impact strength

▪ Good heat stability

▪ Improve melt flow ability

PRODUCT INDEX

|

Item |

Specification |

|

Appearance |

White, free flowing powder |

|

Bulk Density, g/cm³ |

0.40±0.10 |

|

Sieve residue (30 mesh), % |

≤ 2.0 |

|

Volatile content, % |

≤ 1.00 |

BASIC FORMULA FOR THE FOLLOWING TESTS

|

Ingredients |

0# Control |

1# Competitor |

2# MB-200 |

|

PVC (K-57) |

100.00 |

100.00 |

100.00 |

|

Tin stabilizer |

1.20 |

1.20 |

1.20 |

|

Transparent processing aid P-20 |

1.00 |

1.00 |

1.00 |

|

Int. lubricant LU-60 |

1.00 |

1.00 |

1.00 |

|

Ext. lubricant LU-74 |

0.50 |

0.50 |

0.50 |

|

MBS Competitor |

- |

5.00 |

- |

|

MB-200 |

- |

- |

5.00 |

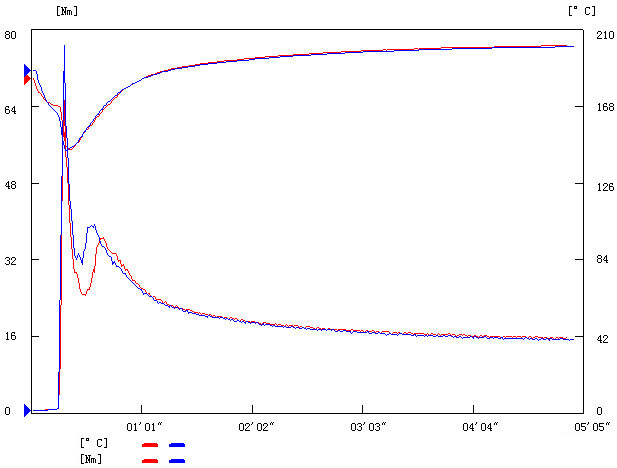

FUSION PROPERTY COMPARISON

|

Test conditions |

160℃ 60rpm |

|||

|

|

||||

|

Fusion/Type |

Fusion time (S) |

Highest torque (Nm) |

Lowest torque (Nm) |

Equilibrium torque (Nm) |

|

1# Competitor |

41 |

43.3 |

20.3 |

22.3 |

|

2#MB-200 |

37 |

46.0 |

23.5 |

22.4 |

|

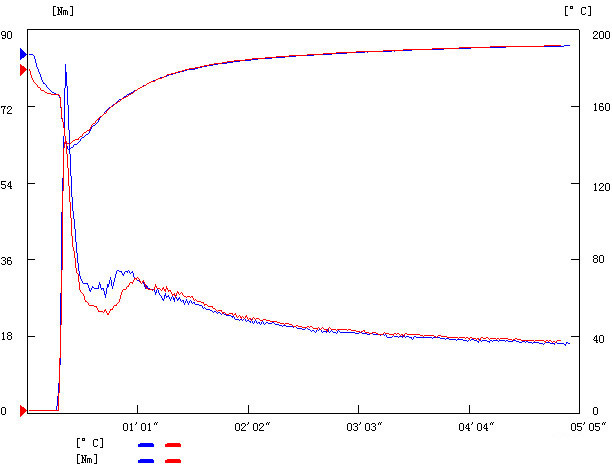

Test conditions |

190℃ 30rpm |

|||

|

|

||||

|

Fusion/Type |

Fusion time (S) |

Highest torque (Nm) |

Lowest torque (Nm) |

Equilibrium torque (Nm) |

|

1# Competitor |

41 |

30.9 |

23.7 |

16.6 |

|

2# MB-200 |

37 |

33.0 |

27.3 |

16.4 |

|

Test conditions |

190℃ 60rpm |

|||

|

|

||||

|

Fusion/Type |

Fusion time (S) |

Highest torque (Nm) |

Lowest torque (Nm) |

Equilibrium torque (Nm) |

|

1# Competitor |

21 |

36.5 |

24.8 |

15.6 |

|

2# MB-200 |

16 |

39.2 |

31.0 |

15.6 |

OPTICAL PROPERTY COMPARISON

|

Type |

Haze (%) |

|

1# Competitor |

4.02±0.04 |

|

2# MB-200 |

3.85±0.03 |

DYNAMIC THERMAL STABILITY COMPARISON

Test condition: double-roller mill temperature190℃ Thickness: 0.5mm

YI at different time Test standard: ASTM E313-00

|

Type |

3' |

5' |

7' |

9' |

11' |

13' |

15' |

|

1# Competitor |

0.95 |

3.20 |

4.57 |

5.68 |

6.67 |

7.85 |

8.90 |

|

2# MB-200 |

0.99 |

3.58 |

4.24 |

5.98 |

7.08 |

8.01 |

9.17 |

MECHANICAL PROPERTY COMPARISON

Pat impact: 5℃stable 20min,25.020HZ pat 15s

|

Type |

Thickness(mm) |

Number of all samples |

Number of damaged samples |

|

0# Control |

0.5±0.02 |

10 |

10 |

|

1# Competitor |

0.5±0.02 |

10 |

1 |

|

2# MB-200 |

0.5±0.02 |

10 |

0 |

-5℃stable 20min, 25.020HZ pat 15s

|

Type |

Thickness(mm) |

Number of all samples |

Number of damaged samples |

|

0# Control |

0.5±0.02 |

10 |

10 |

|

1# Competitor |

0.5±0.02 |

10 |

2 |

|

2# MB-200 |

0.5±0.02 |

10 |

1 |

TENSILE STRENGTH COMPARISON

Test standard: GBT 1040-2006 Test condition: 23℃ 10mm/min

|

Type |

Tensile strength (MPa) |

Elongation at break (%) |

|

0# Control |

46.71±0.24 |

115.64±4.12 |

|

1# Competitor |

45.20±0.43 |

157.04±3.54 |

|

2# MB-200 |

45.24±0.46 |

164.89±4.51 |

METAL RELEASE PROPERTY COMPARISON

Test condition: Double-roller mill temperature 196℃

|

Type |

Sticking time(S) |

|

0# Control |

340±10 |

|

1# Competitor |

504±12 |

|

2# MB-200 |

513±12 |

STORAGE

The product should be stored in cool and dry surroundings.

The shelf life is two years, it can be still used if qualified by inspection after shelf life.

PACKAGE

25kg/bag with PP bag or customized packaging according to customer requirements.

LOADING CAPACITY

For 20GP container, we can load 16mt with pallets or 18mt without pallets.

For 40HC container, we can load 28mt with pallets or 28mt without pallets.

Factory

Customer visits

Delivery site

GET A FREE QUOTE

If you have any questions, please feel free to leave us a message at any time